Improving Performance of Hobbyist CNC Mill

Spring 2021, 2.72 - Elements of Mechanical Design project

Skills Demonstrated

- Team Work

- Simulation Experiments

- Physical Hardware Experiments

- Matlab

- Stress Analysis

- Machine Design

Project Description

This purpose of this project was to improve certian performance metrics of the Snap Maker 1.0. This included:

- Reduce total position error in y to < 100 μm

- Kinematic coupling repeatability in positioning in x and y to be < 25 μm

- Deflection of Kinematic coupling in x,y,& z < 25 μm

- Improve axes alignment to <0.5 degrees

- Decrease nosie level 30 cm away to less than 75 dB

- Vibration deflection to less than 25 μm

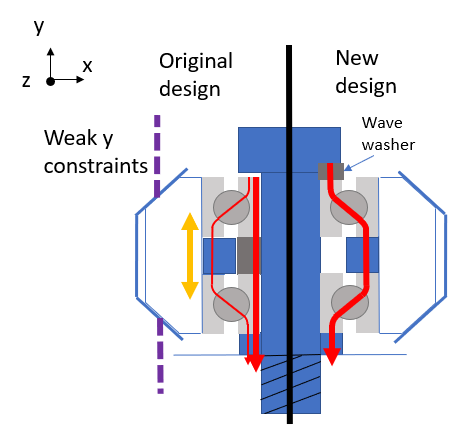

Additionally, we made small design changes to the sliding carriage to increase stiffness to reduce position error at the tool tip.

Above shows a source of the positional error - play in the sliding carriage due to a lack of preload on the bearings.

Above shows the design changes to properly preload the bearings.

Results:

- Reduced tool tip deflection from 0.060” to 0.039” (1.52 mm to 0.99 mm) under applied load of 𝐹_𝑦=-15 N (35% reduction in error).

- Kinematic Coupling: Repeatability: x, y = 0.001” (25.4 μm) Deflection: < 25.4 μm/0.001” for 15 N load in x, y, z

- Z and Y rail: 𝜃_𝑧 = 0.21° -> 𝜃_𝑧 = 0.0713° angular misalignment, => 34% reduction, Z to X rail: 𝜃_𝑧 = 0.5° -> 𝜃_𝑧 = 0.2° => 60% reduction

- Decreased reduced measured deflection at CNC head by 0.002” & noise by 10 dB